Most of the early PCB boards used soldering methods, but with the upgrading of electronic products, miniaturization of connectors, and requirements for high reliability and environmental protection, crimping has become the main connection method. There are many types of

connectors , which can basically be divided into two categories: wiring (connected to the cable) and connection board (connected to the PCB). Crimp and Press-in are the most common connection methods in these two categories. Interestingly, the Chinese of these two connection methods can be expressed by the word "crimp".

Board technology Press-in: low cost and high efficiency

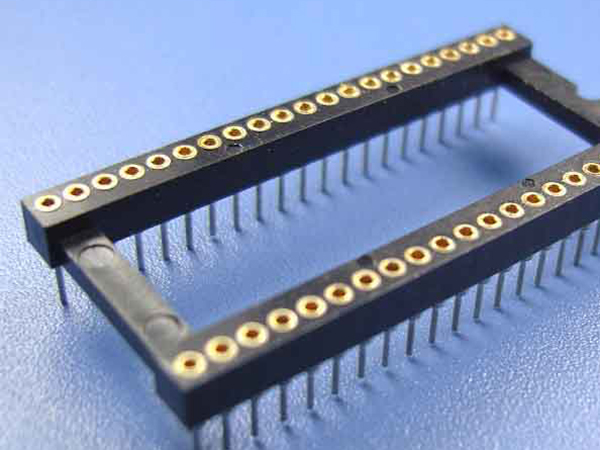

The definition of a press-in connector is that a pin (also called a terminal) is pressed into a hole smaller than its outer diameter by external force. This press-in connection method is called Press-fit, also called Crimp. Because it is lower in cost, higher in efficiency, simpler in operation, and more reliable than SMT (that is, surface mount technology, which is a splicing technology), it is widely used in communication and computer industries.

Press-fit connectors also have a special application for the interconnection of three boards. Compared with the welding technology that can only be used for two-dimensional panels, it has a wider range of uses. Its disadvantages are the high requirements for PCB boards and the complex testing. ..Wait.

Contact: Ms Zhao +86-13650012366

Contact: Ms Zhao +86-13650012366

Contact: Mr Li +86-13926843468

Contact: Mr Li +86-13926843468

E-mail: sales@dniceconn.com

E-mail: sales@dniceconn.com

E-mail: rubyzhao163@163.com

E-mail: rubyzhao163@163.com

Add: No.2,Yuan Fu road, Yuan Jiang Yuan village, Chang

Add: No.2,Yuan Fu road, Yuan Jiang Yuan village, Chang

Public account

Public account Add WeChat

Add WeChat Mobile site

Mobile site Mini Program

Mini Program