(一) Material material

Contacts and bushing materials should be conductive, and the sheath should be made of stainless steel; when incompatible metals are used in contact with each other, appropriate anti-electrolysis should be adopted Corrosion protection measures.

Good conductivity: low resistivity, which reduces the temperature rise when the current passes;

Good elasticity: The displacement of the metal spring is proportional to the contact pressure within the elastic limit. If the displacement exceeds the elastic limit, it will cause permanent deformation. Compared with the original elastic characteristics, the contact pressure will be smaller.

Good corrosion resistance: Sometimes high-current, high-voltage contacts are not surface-treated, so they must have good corrosion resistance, and noble metal layers also inevitably have plating pores, and the base metal will pass through. The pores are corroded.

Good processability: reduce costs.

Other aspects: crimping of the crimp type (good elongation of the material), weldability of the weld type, stress corrosion cracking, seasonal cracking, etc.

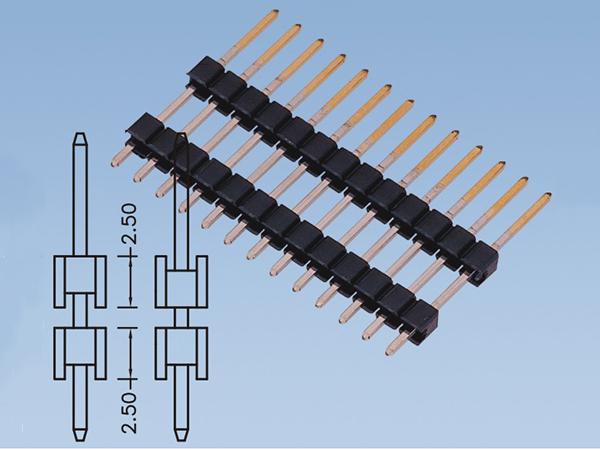

(two) plating

The thickness of the silver-plated layer on the surface of the contact should be greater than 5um, and the thickness of the gold-plated layer on the bottom layer should be at least 1um (the product's military standard generally requires 1.27um). . When local plating is used, the length of the noble metal plating should be equal to the maximum triboelectric contact length plus at least 0.5mm. The non-contact parts are tin-lead alloy plated, containing 50-90% tin, and the thickness is at least 2.5um.

Contact: Ms Zhao +86-13650012366

Contact: Ms Zhao +86-13650012366

Contact: Mr Li +86-13926843468

Contact: Mr Li +86-13926843468

E-mail: sales@dniceconn.com

E-mail: sales@dniceconn.com

E-mail: rubyzhao163@163.com

E-mail: rubyzhao163@163.com

Add: No.2,Yuan Fu road, Yuan Jiang Yuan village, Chang

Add: No.2,Yuan Fu road, Yuan Jiang Yuan village, Chang

Public account

Public account Add WeChat

Add WeChat Mobile site

Mobile site Mini Program

Mini Program