A. What is a connector?

Electronic connector refers to the connection unit between various electronic components, mainly used as chip-to-circuit board, circuit board-to-board and box-to-box electronic signal connection and transmission. In terms of types, it can be divided into substrate connectors, angular connectors, cylindrical connectors, and popular PCMCIA connectors.

Although the definition of electronic connectors has always been unclear, the scope of its coverage, general understanding does not include high voltage, high current appliances or electrical connectors other than power plugs or sockets: electrical switches do not include large internal .Most people in the industry in Japan directly use the transliteration of English (Connector), sometimes called [continuous piece], and in China use [electrical plug] or [electrical connector] including connectors and switches, regardless of connectors A broad term for electronics and electrical appliances. As far as applications are concerned, most electronic connectors are used in computers, telecommunications, aviation, automobiles and various instruments.

二. Application of connector

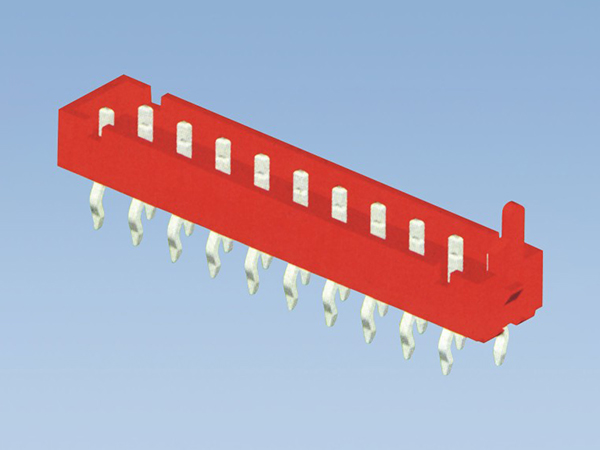

Electronic connector is used in electrical products. As the name implies, it plays the role of electronic number or component connection. It is a multi-functional merged or assembled product. It is covered with metal sheets, surface plating, precision machining and plastic molding. And other key technologies. As the transmission and connection of electronic numbers, if there is a problem with the electronic connector, it will cause the electronic components and even the entire equipment to fail. The entire connector includes two main parts: terminals and plastic. In addition to the selection of materials, the terminal parts are electroplated and The quality of the die will affect the quality of the product. Of course, the same is true for the plastic part.

.

Three. Manufacturing of connectors

The manufacturing of electronic connectors can be divided into metal and plastic from design to finished product. In addition to the selection of materials for metal parts, electroplating and punching are the main tasks; plastic mold work is the design of plastic molds. Mold, injection molding, and then cooperate with metal components to form an electronic connector. Electronic connectors are used in electrical products. As the name implies, it is a connection that plays an electronic signal or component. Sheet, surface electroplating, precision processing and plastic molding. As the transmission and connection of electronic signals, if problems occur in the electronic connector, some of them will be affected except for the selection of materials. The quality of the plating and die will affect the quality. The quality of the product, of course, is the same for the plastic part. Its manufacturing includes five major technologies: 1. die technology 2. injection molding technology 3. electroplating technology 4. assembly technology 5. inspection technology. Due to the trend of connectors, they are becoming thinner and shorter. SMT, so the various manufacturing technologies required also need to quickly improve its accuracy requirements.At the same time, the precise concept of the manufacturer also needs to be changed in order to produce precise connectors, otherwise the connectors will be in the future. Let the market, will be eliminated, because quality can not compete electronic components and even entire equipment failure. The connector includes a terminal and the entire plastic part of two major terminals.

Contact: Ms Zhao +86-13650012366

Contact: Ms Zhao +86-13650012366

Contact: Mr Li +86-13926843468

Contact: Mr Li +86-13926843468

E-mail: sales@dniceconn.com

E-mail: sales@dniceconn.com

E-mail: rubyzhao163@163.com

E-mail: rubyzhao163@163.com

Add: No.2,Yuan Fu road, Yuan Jiang Yuan village, Chang

Add: No.2,Yuan Fu road, Yuan Jiang Yuan village, Chang

Public account

Public account Add WeChat

Add WeChat Mobile site

Mobile site Mini Program

Mini Program